Apart from traditional foundry services (Design Kits Delivery, manufacturing), UMS has developed a large range of optimised services to minimise lead time and shorten design cycle.

Testing is performed in the controlled environment of a class 10000, 700m2 clean room.

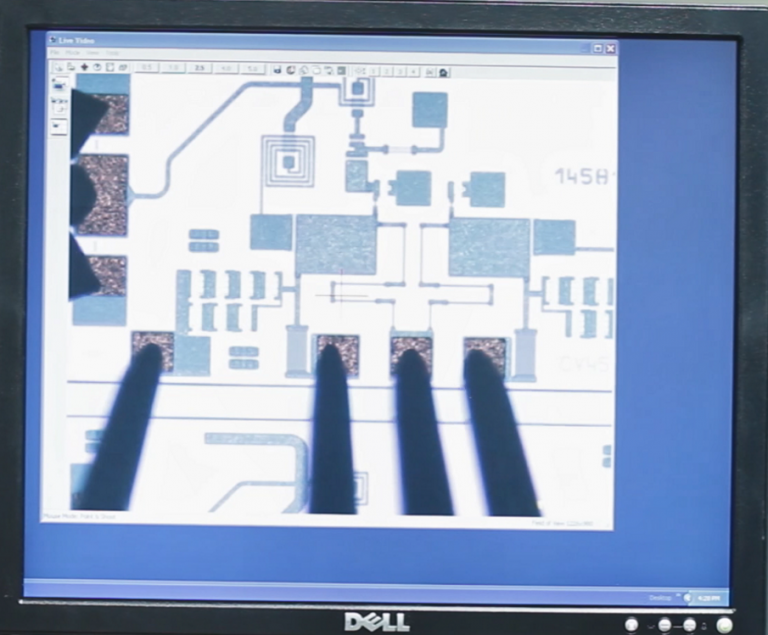

You will benefit from an unique set of automated on-wafer testing solutions for circuit characterization and sorting according to your product specifications. 17 automatic test stations enable full circuit characterization from 1 to 110GHz.

100% functional on-wafer tests are available (S-parameters, DC, noise, CW or pulsed power).

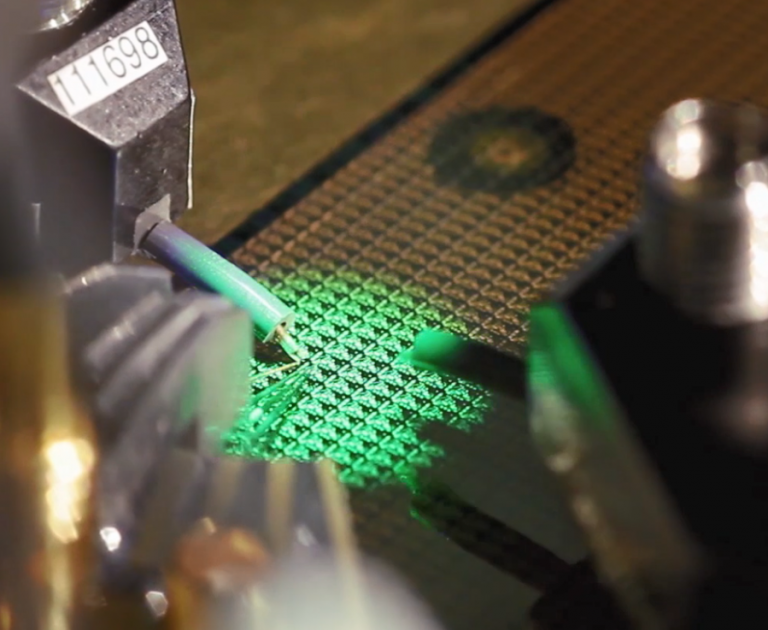

Dicing: UMS benefits from laser dicing equipements for GaAs.

Visual inspection: Your circuits can benefit from visual inspections according to your required commercial or space screening level.

Picking: According to your sorting criteria, the individual die numbering allows identification of your chips. Known Good Die may be delivered in Gel-Pack®, waffle pack or on UV-film.

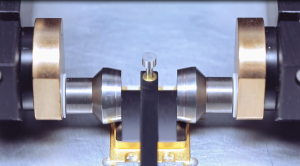

UMS has qualified a in-house prototyping assembly line for small quantity of chips assembly in package or on board for demo or test jigs.

This line includes at least:

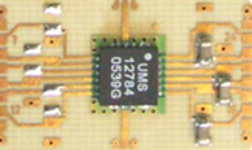

UMS is enlarging its GaAs foundry offer with standard molded plastic packaging. This new offer enables single chip low cost plastic encapsulation of your circuits developed on UMS processes with the BCB option.

8 standard QFN packages from 3x3mm2 to 6X6mm2 are offered. ADS models are available in the associated Design Kit for packaged MMIC designs.

This offer is available for production or prototyping runs with a minimum quantity.

Contact us @ mktsales@ums-rf.com