Shared foundry runs or Multi-Project Wafers are a cost effective foundry approach well suited for Institutes, Labs, Research Centers and Universities. This service allows different customer projects on a single wafer.

You will be able to:

Participants have free access to Design Kits. 20 diced & untested MMICs in Gel-Pak® box will eventually be delivered.

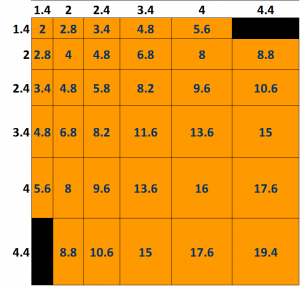

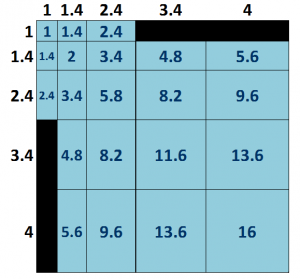

The possible die length and width, including dicing streets, are:

with maximum aspect ratio 1:3

with maximum aspect ratio 1:3

Price is determined according to die area and process.

UMS shared foundry runs offer regular Multi Project Wafer runs with information 6 months notice before tape-out.

Shared foundry runs 2024-2025

Next low-medium power process runs

Next High Power Process run:

Next GaN Hemt process runs

Shared runs are scheduled based on customer needs. UMS optimize schedule to meet tape-out date that maximize delivery time agreement with customers.

If you are interested by our Shared Foundry runs or if you have wishes, please fill in the questionnaire below: